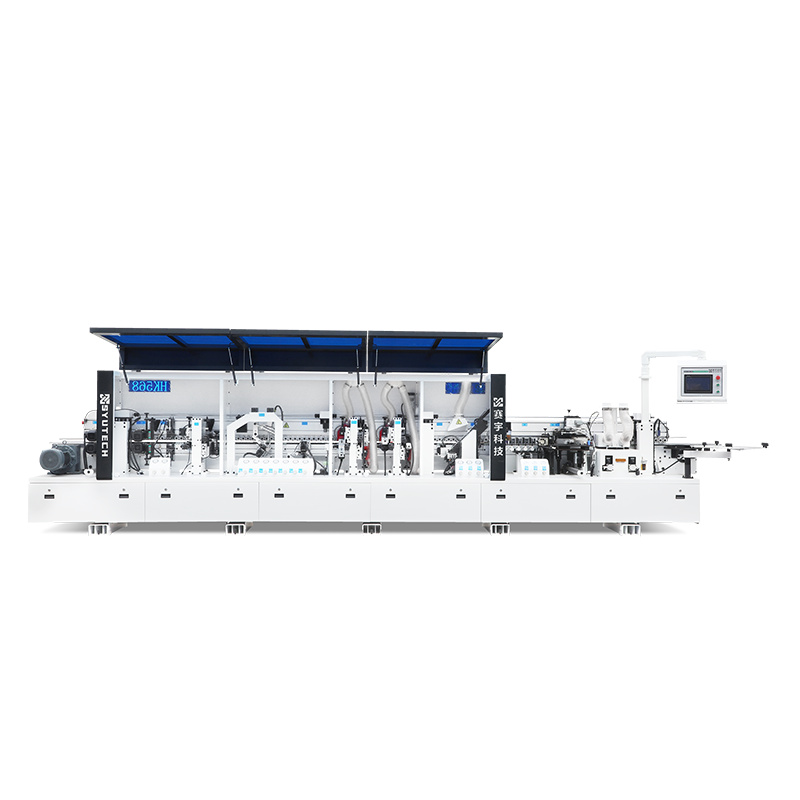

Umshini wokuhlanganisa onqenqemeni othomathikhi ngokugcwele usetshenziselwa ikakhulukazi ukukhiqizwa kwefenisha yephaneli neminyango yamapulangwe, futhi unomphumela obaluleke kakhulu ifenisha ehlukahlukene yokhuni, iminyango yokhuni neminye imikhiqizo. Imisebenzi ihlanganisa ukugaywa kwangaphambili, ukunamathiswa, ukusika, ukusika amaholoholo, ukusika kahle, ukukhuhla, ukugoqa emakhoneni, ukupholisha, ukugoqa, njll. Kuyisisizi esihle sokukhiqizwa kwemikhiqizo yokhuni.

Ukugaya ngaphambilini :Sebenzisa izinqamuleli zokugaya kabili ukuze uthinte kabusha ama-ripple marks, ama-burrs noma izenzakalo ezingaqondile ezibangelwa ukusaha kwephaneli nokucutshungulwa kwesaha ukuze uzuze imiphumela engcono yokuvala onqenqemeni. Ukuhlangana phakathi komugqa onqenqemeni nebhodi kuba kuqina futhi ubuqotho nobuhle bungcono.

I-Gluing : Ngesakhiwo esikhethekile, ibhodi elibopha onqenqemeni kanye nezinto zokubopha onqenqemeni zimbozwa ngokulinganayo ngeglu ezinhlangothini zombili, okuqinisekisa ukunamathela okuqinile.

Qeda ukunquma :Ngokunyakaza komugqa oqondile, ukulandela ngomkhondo okuzenzakalelayo kwemodeli kanye nesakhiwo sokusika esisheshayo samamotho anemvamisa ephezulu kanye nesivinini esikhulu kuyasetshenziswa ukuze kuqinisekiswe ukuthi indawo yokusika iyisicaba futhi ibushelelezi.

Ukusikwa okungalungile, ukunquma kahle:Zonke zisebenzisa imodeli yokulandelela okuzenzakalelayo kanye nesakhiwo semoto esinesivinini esikhulu semvamisa ephezulu ukuze kuqinisekiswe ukuthi izingxenye ezingenhla nezingezansi zepuleti elisikiwe ziyisicaba futhi zibushelelezi. Isetshenziselwa ukulungisa nokukhipha okusele okuhlanganisiwe okusemaceleni ezinhlangothini ezingaphezulu neziphansi zomugqa webhande onqenqemeni webhodi elicutshunguliwe. Ummese wokusika omangelengele umbese oyisicaba. Ukuze kucutshungulwe izingxenye ezisele ze-veneer yokubeka uphawu. Ngoba lapho uvala i-veneer, awukwazi ukusebenzisa ngokuqondile ummese wokuqedela omise okuka-R. I-veneer ngokuvamile inobukhulu obungu-0.4mm. Uma usebenzisa ummese wokuqeda ngokuqondile, kuzokwenza kalula ukuqhekeka. Ngaphezu kwalokho, ukulungisa okungalungile kungasetshenziswa futhi ukuvala i-PVC ne-acrylic. Chofoza isixhumanisi sedokhumenti ukuze uhlole ulwazi olwengeziwe. Chofoza isixhumanisi sedokhumenti ukuze uhlole ulwazi olwengeziwe mayelana nenqubo yokuqala yokulungisa ifulethi. Ummese wokuqedela uwummese omise okwe-R. Isetshenziselwa ikakhulukazi i-PVC kanye nemicu ye-acrylic edge yefenisha yephaneli. Kukhethwa amapheshana onqenqema anogqinsi luka-0.8mm noma ngaphezulu.

Ukuzungezisa amakhona :Imishini yokuzungeza ephezulu naphansi ingenza ubuso besiphetho sepuleti bushelelezi futhi bube buhle kakhulu

Ukuklwebha :Isetshenziselwa ukuqeda izimpawu ezinyakazayo ezibangelwa inqubo yokusika engaqondile yokunquma, okwenza izingxenye ezingaphezulu nezingezansi zepuleti zibe bushelelezi futhi zibe bushelelezi;

Ukupholisha:Sebenzisa isondo lokupholisha ukotini ukuze uhlanze ipuleti elicutshunguliwe bese ulipholisha ukuze wenze indawo yokuphela kwayo ibe bushelelezi.

I-Grooving: Isetshenziselwa ukugoba okuqondile kwamaphaneli aseceleni ekhabethe, amaphaneli aphansi, njll., okunciphisa inqubo yokusaha iphaneli futhi kulula kakhulu futhi ngokushesha; ingabuye isetshenziselwe ukuhlanganisa i-aluminium ye-grooving yamapaneli eminyango.

Izinyathelo zokuqapha:

1. Okokuqala, kuyadingeka ukwenza ukugcinwa okuvamile emshinini wokubopha onqenqemeni. Ngokuvamile, umjikelezo wokugcinwa kwe-umshini wokuhlanganisa onqenqemenicishe izinsuku ezingama-20. Kumele kuqashelwe ukuthi ngesikhathi senqubo yokulungisa, ukuguga nokudilika kwama-bearings, amagiya, imizimba eccentric nezinye izingxenye kufanele kurekhodwe ngokuningiliziwe.(Edge Banding Machinery).

2. Umshini wokuhlanganisa onqenqemeni(Wood Edge Banding Machine)kufanele ihlanzwe ngokwezinga elithile ngemva kokuba umsebenzi usuqediwe ukuze kukhucululwe ukungcola okuthile okudaleke phakathi nenqubo yokusebenza ukuze kugwenywe ukuvala ngokuzayo lapho isetshenziswa.

3. Yenza njalo ukwelashwa kwesistimu yokugcoba emshinini wokubopha onqenqemeni. Lapho ukhetha uwoyela wokugcoba, naka ukukhetha ikhwalithi enhle.

4. Ngemva kweumshini wokuhlanganisa onqenqemeniisetshenziswe isikhathi esithile, zonke izingxenye zomshini wokubopha onqenqemeni kufanele zihlolwe. Uma kukhona ukuntenga, kufanele kuxazululwe ngokushesha. Ukuvikelwa nokugcinwa komshini wokuhlanganisa onqenqemeni kudlala indima ebalulekile ekusetshenzisweni komshini wokuhlanganisa onqenqemeni. Ngakho-ke, uma usebenzisa umshini wokubopha onqenqemeni nsuku zonke, ungakhohlwa ukwenza ukugcinwa okuvamile emshinini wokubopha onqenqemeni.

Uma unemibuzo ethile mayelana nalolu lwazi, sicela ukhululeke ukubuza!

Sikhethekile ekukhiqizeni zonke izinhlobo umshini woodworking,cnc umshini wokumba ohlangothini oluyisithupha,i-computer panel saw,isidleke se-cnc router,umshini wokuhlanganisa onqenqemeni,isaha letafula, umshini wokubhoboza, njll.

Tel/whatsapp/wechat:+8615019677504/+8613929919431

Email:zywoodmachine@163.com/vanessa293199@139.com

Isikhathi sokuthumela: Mar-27-2024